Perforate Metal Sheet

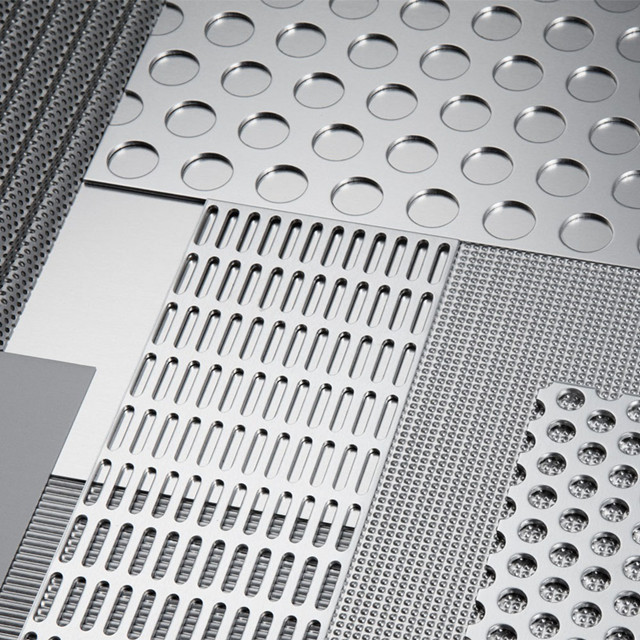

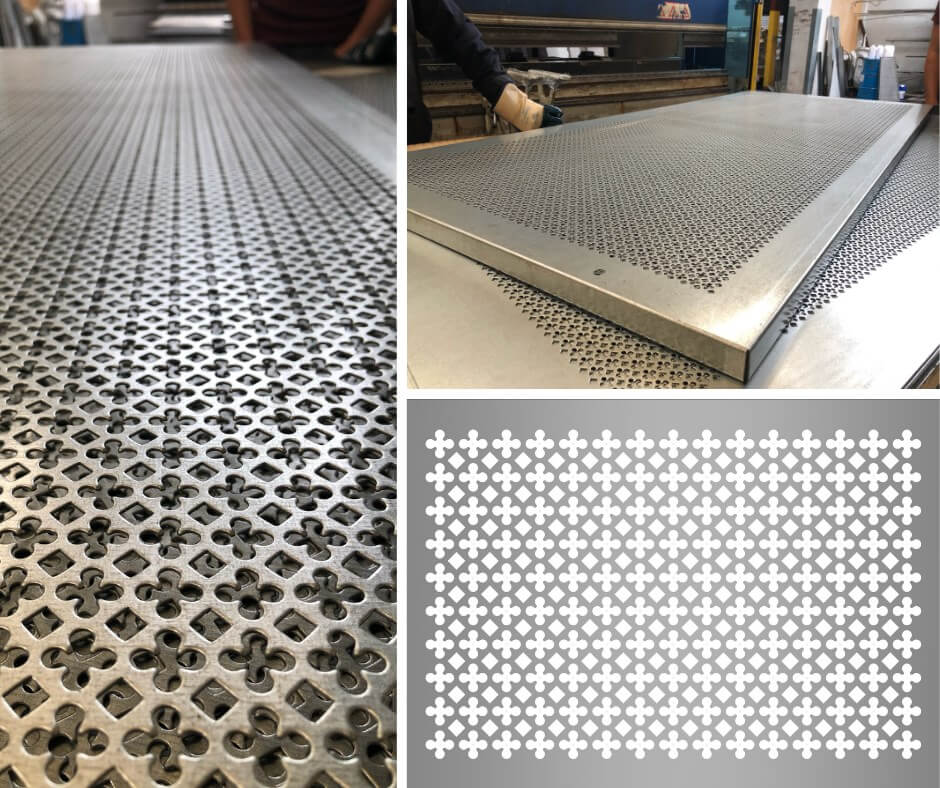

Perforated Metal Sheet also known as punching mesh,perforated plate,perforated screen,peforated panel,etc.It refers to the surface of all kinds of shaped holes of the metal sheet products are widely used in chemical machinery,pharmaceutical equipment,food and beverage machinery,cigarette machinery,harvester,dry cleaning machine,ironing table,silencer equipment,refrigeration equipment (central air conditioning) speakers, crafts,paper making, hydraulic accessories,filtration equipment and other industries.Hole type rectangular hole,square hole,diamond hole,round hole,hexagonal hole,cross hole,triangle hole,slotted hole,fish scale hole,pattern hole,irregular hole,drum hole,etc.

Perforated metal sheet is through punching or shearing,bending or multiple bending forming,deep drawing forming,deep drawing forming and blanking or precision blanking.

Features:

1,It can effectively reduce the nosie.

2,Aluminum and stainless steel sheets have strong corrosion resistance.

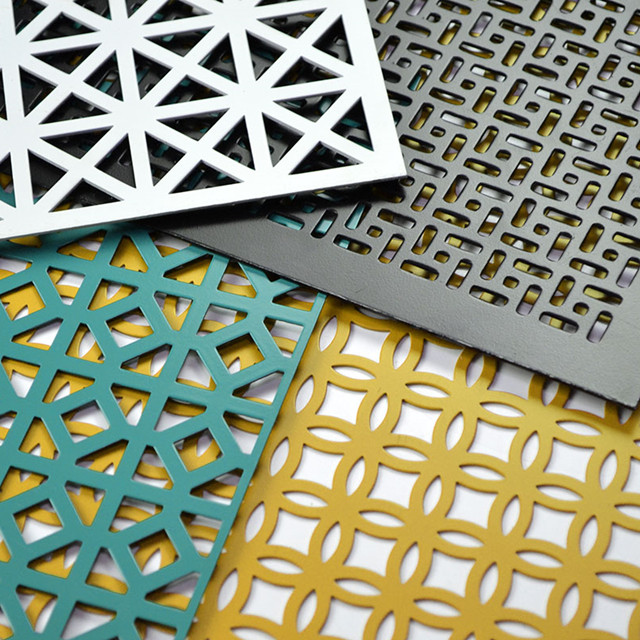

3,Aperture can be customized accroding to requirements,for different scenes,filtering,decoration,enclosure,etc.

Material:

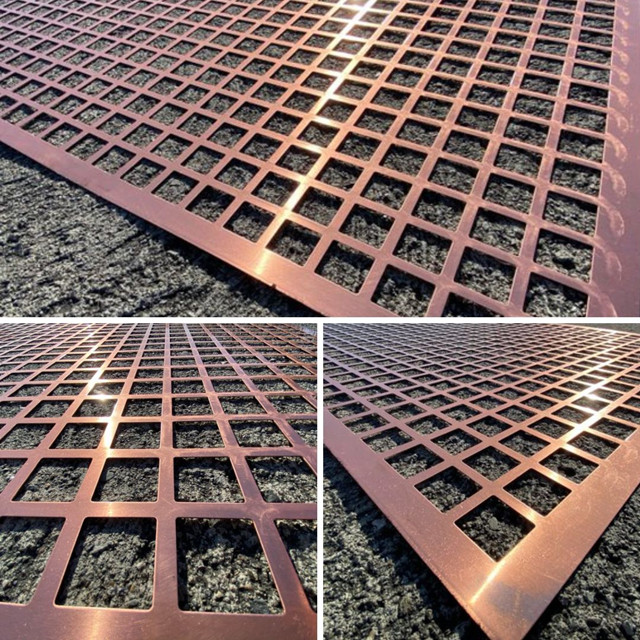

Stainless steel,aluminum,galvanized steel,mild steel,copper,etc.

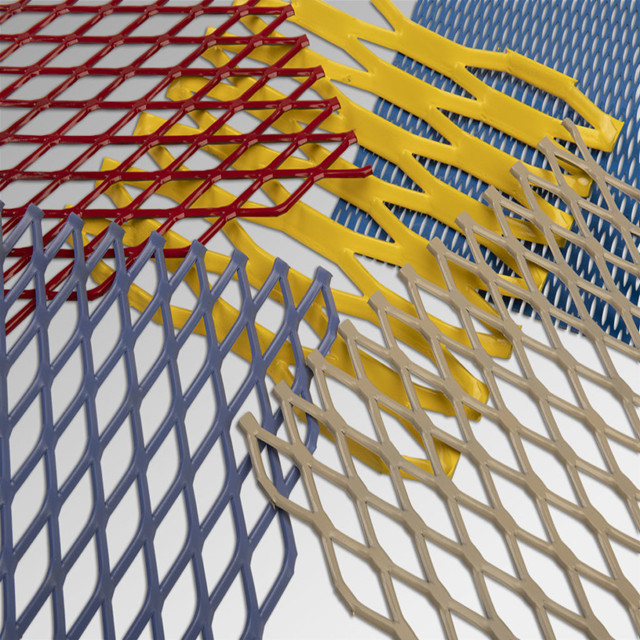

Hole shape:

Round hole,square hole,rectangular hole,slotted hole,hexagonal hole,diamond hole,etc.

Hole diameter:

From 1mm to 50mm.

Thickness:

From 0.1-30mm.

Standard Size:

1000x2000mm;1200x2400mm;1220x2440mm;1250x2500mm,etc.

1.Die:

Punching process is inseparable from the production of precision die.The quality of the product depends on the accuracy of the die.We have have been working in this field for many years,and have made the biggest improvement to our machine for die production.

2.Perforating:

We use the most advanced CNC machines for processing and production.The day output is over 20000㎡.We can fabricate the material thickness from 0.1 to 30mm.

3. Shearing:

We have 5 sets of precise shearing equipment to ensure all errors within the minimum range,the workers who operate the machine are also experienced in shearing for more than 10 years.

4. Roller Leveling

We can make the perforated panels thickness arrange from 0.8mm-15mm back to the original flat with imported leveling machine.

5. Cleanliness

The punching process requires the use of lubricants,and a degreaser steps can be applied to clean oil free from the material surfaces.

6. Surface treatment:

Surface can be Electric galvanized,hot-dipped galvanized,powder coating,pvc coating as customized.

1.Filter.

2.Decorative panels.

3.Anti-skid plates.

4.Funiture.

5.Building Facade.

6.Air conditioner.

7.Industry

Products Inquire